VPSA Oxygen Gas Generator

The core process flow of the plant is to use air as raw material and vacuum pressure swing adsorption (VPSA) process to separate and extract oxygen enrichment.

Lead Time:

30daysProduct Orgin:

Guangzhou,ChinaShipping Port:

GuangzhouPayment:

This supplier also supports L/C,D/A,D/P,T/T,WPrice:

$50000/setMarket Price:

$100000Color:

whiteMedical Oxygen Gas Generator

Principles

Tech-principle of PSA Oxygen Generator

Nitrogen and oxygen both with quadrupole moment,due to nitrogen’s(0.31Å)is bigger than oxygen’s(0.10Å), the zeolite molecular sieve adsorption passing cross the adsorbent bed filled with zeolite, N₂ adsorbed by zeolite, the oxygen molecular excluded out,separation process finished for collecting O₂ purpose.

The zeolite adsorb N₂ nearly full, the pressure reduce and air stop inlet, N₂ can be desorbed form zeolite, and recyling usage.

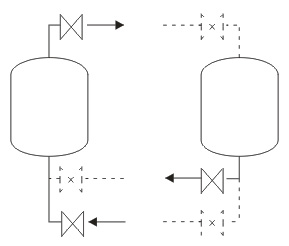

The two towers of the oxygen generator,one is adsorbing to produce oxygen,another is desorbtion regeneration,cyclic alternating, continuous to manufacture O₂

Equipment Structure

The Structure of PSA Oxygen Generator

1. Compressed air purification system

1.Remove dust、water and oil in the compressed air, mainly composed of the three grade filters, freezing-drier,and efficient oil removal.

2. Air Buffer system

2.Ensure the stable supply of gas for O₂/N₂separation system, mainly composed of air tank and valves.

3. Oxygen and Nitrogen Separation System

It’s the core of the whole equipment. It produduces O₂ with the PSA technology,which composed of the automatic control valves and tow adsorption towers filled with zeolite molecular sieve.

4. O₂Buffer System

Storage O₂for ensuring the supply smoothly and continuously,composed of O₂ buffer tank, valves and other components.

5. Electrical Control System

It’s the control center of the whole equipment, composed of PLC, electrical systems,instrumentation and valves.

Characteristics

◆The mechatronics design realizes the automatic running

Imported PLC control runs full-automatic. The purity, Pressure and flow of oxygen are adjustable and displays in succession, which can set the pressure, flow, purity alarm realize remote automatic control, measurement&test, to realize real unmanned operation.The advanced control system makes it simple and easy to operate, automatic switch ON/OFF according at the O₂usage consumption.Normal running service life can be up to 8~10 years.

Specification&Selection

|

Model |

Flow/Capacity |

External Dimension |

|

|

|

WG-STDO-1 |

1 |

1200×650×1300 |

machine |

|

|

WG-STDO-2 |

2 |

1200×650×1900 |

||

|

WG-STDO-3 |

3 |

1200×1100×1900 |

|

|

|

WG-STDO-5 |

5 |

1500×1350×1900 |

||

|

WG-STDO-10 |

10 |

1600×1450×2200 |

||

|

WG-STDO-15 |

15 |

1450×850×2250 |

main part |

|

|

WG-STDO-20 |

20 |

1500×945×2470 |

||

|

WG-STDO-30 |

30 |

1560×1000×2780 |

||

|

WG-STDO-50 |

50 |

1960×1160×2640 |

||

|

WG-STDO-80 |

80 |

1960×1350×3330 |

||

|

WG-STDO-100 |

100 |

2150×1400×3260 |

||

|

WG-STDO-120 |

120 |

2500×1625×3480 |

||

|

WG-STDO-150 |

150 |

2750×2125×3360 |

||

|

WG-STDO-180 |

180 |

2850×1990×3580 |

||

|

WG-STDO-200 |

200 |

3050×2200×3550 |

O₂ Purity:93%

O₂ Flow:1~200Nm3/hr

O₂ pressure:1-5bar

Dew Point -40℃

(Customized purity to99%)

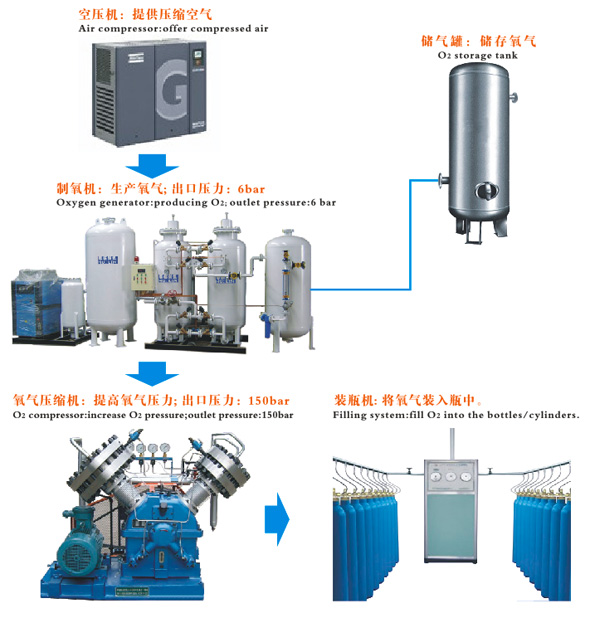

Botting

Advantages

3. Steady-going, long life-span

Unique clamping cylinder technology effectively extending the life of molecular sieve.

4. High degree of automation

The automatic control technology could switch machines with one key, and have remote and centralized operation with nobody control.

Application

1. Used in hospitals to provide oxygen for patients.

2. Used in industry, such as welding, etc.

3, for animal husbandry, aquaculture, such as the pond fish to provide adequate oxygen.

4. Other places that need oxygen, oxygen bottle, etc.

Why choose us

1. We have more than 10 years of experience in air separation equipment and have rich experience in facing all difficulties.

2. Our delivery cycle is short. The soonest we can deliver the goods is 15 working days since we pay the deposit.

3.We have professional engineers in charge of after-sales service, which can be provided anywhere in the world.

4, we have a unique technology, so that the life of the molecular sieve more than 10 years.

All our machines are fully automated and there is no need for guards.

6. Our machines save 10%~20% more energy than our counterparts.

Online Service

Online Service Tel:+86 13710712082

Tel:+86 13710712082 huilin@world-gas.cn

huilin@world-gas.cn WhatsApp:+8613724819737

WhatsApp:+8613724819737